We all know the old saying: “Oil and water do not mix.” Well here’s a new one: “Fuel and water DO MIX resulting in fuel contamination by microorganism growth.”

Living in Florida we are no strangers to the extreme fluctuations in weather, high temperatures, bouts of heavy rain, muggy conditions and consistently high levels of humidity; all of which greatly increase the chance of water contamination of fuel in both transportation and storage. Once you have water in the system, you are set for an invasion of microorganisms.

Monitoring and treatment of water contamination is important to safeguard your business and maintain good customer relationships. Without a comprehensive maintenance plan your storage system is vulnerable to degradation of fuel, damage to vehicle performance, equipment breakdowns and damage to the entire storage system. Your tank, being the most common collection site where chemical reactions take place, provides an easy controlled environment for monitoring, maintenance and treatment.

How exactly does enter your trusty storage system you ask?

?o?o?o?o?o?o?o?o?o?

There is the possibility water was in the product delivered. This situation rarely happens, so let’s look at more common ways water can end up in a storage tank:

- Damaged fill boxes or fill cap gaskets

- Loose fittings or plugs

- Poor practices with fill buckets

- Rainwater accumulation in tank sumps (from the sump water can enter through any hole in tank that is not water tight or sealed)

- Condensation by fuel temperature swings

- Air enter via vents

Let’s take a look at one particular example: contamination through ventilation.

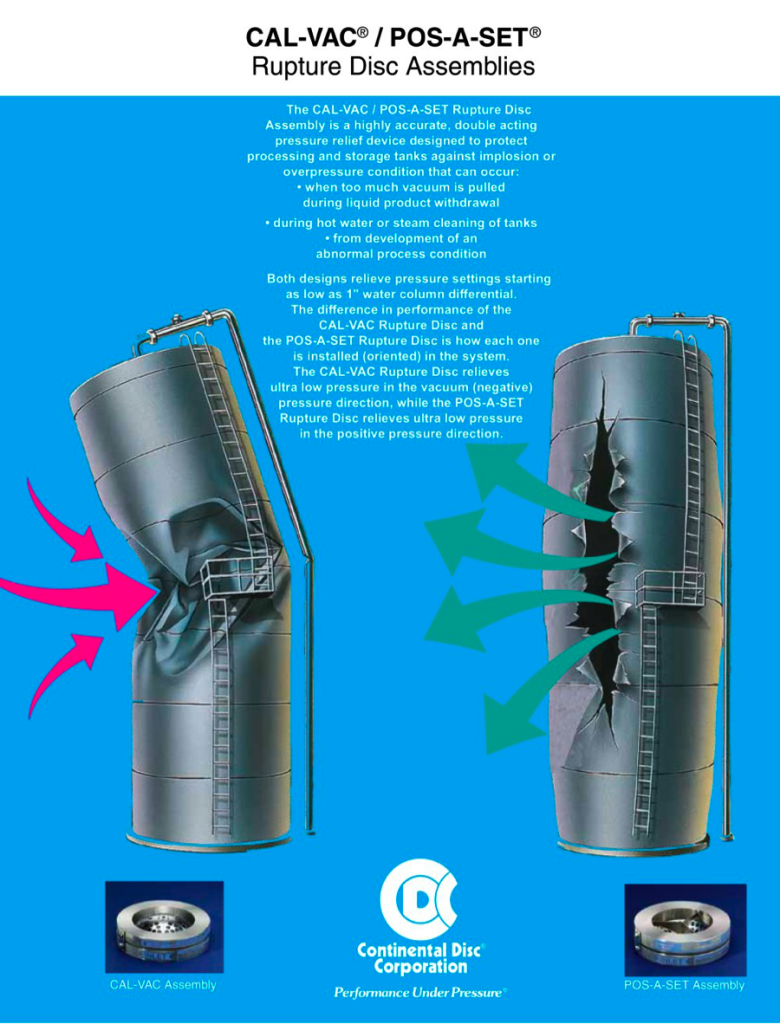

All tanks stored above ground need to be properly vented to handle the pressure changes that occur as a result of pumping fuel in and pumping fuel out. Filling a tank results in displacement of air out, also known as out-breathing. Emptying a tank results in the atmospheric air being drawn in, also known as in-breathing. You can see how ventilation is important: excessive vacuuming and/or increased pressure could distort and rupture the tank’s structure.

So we now understand the IMPORTANCE and NECESSITY of proper tank ventilation; no one wants to ever have a situation like the one above on their hands.

How do tank ventilation and contamination tie together? The vents pull in outside air that may contain humidity, dust, mold spores, bacteria and other contaminants. This creates a possible environment for water contamination.

Getting back to the bigger picture….

The possible problems that can occur due to water contamination are as follows:

- Formation of sludge that will cause clogs in fuel lines, nozzles, filters and screens (pretty much suffocate your whole storage system with ‘water snot’)

- Degradation in fuel quality which results in poor vehicle performance, equipment failure failed exhaust emissions and possible major engine damage.

- Excessive maintenance cost

- Fuel leaks that lead to environmental damage with costly clean-up and facility downtime/lost business.

Signs of microbial growth:

The most common sigh of microbial growth is clogged fuel filters caused by the slime created by the microorganism colony blocking small filter openings. You will notice the total life of your filter cut in half and very slow fuel flow when pumping. Other signs to look out for:

- Plugged fuel lines

- Erratic gauge readings

- A rotten egg smell

- Unusual replacement of valves, rubber seals and hoses in equipment

- Unusual exhaust smoke.

LUCKY FOR YOU LYNCH OIL IS HERE TO THE RESCUE!

LUCKY FOR YOU LYNCH OIL IS HERE TO THE RESCUE!

The staff at Lynch Oil Company are trained to contamination experts. We are given the knowledge and tools to:

- Be aware of storage tank situations that are in high risk of contamination

- Positively identify a contaminated storage system

- Treat and eliminate the situation

- Train and educate our customers to be aware and preventative.

Here at Lynch Oil we offer biocide tank treatments (H.U.M OUT) that control bacteria and fungi growth in your storage tanks. In addition to biocide as a tool to fight contamination we also use high quality fuel filters, CIM-TEK Hydrosorb Particulate & Water Removal, combining these tools will protect your tank & fleet!!.

Bacteria is not completely eliminated by biocide treatments. The dead bacteria will continue to cycle through your system, which does not completely rid your fuel of the contamination. These dead microbes will wax and clog filters leading to more issues in work efficiency and excess maintenance costs. The best way to handle bacteria is to treat the fuel and replace the filter. Lynch Oil offers a filter replacement program and reoccurring tank treatments. We calculate our treatment plans on intervals based on monthly fuel usage and adjust to your schedule.

Call us for a free tank assessment! As we said in the beginning: “Fuel and water DO MIX.” But as we have learned: “Fuel, water and business efficiency DO NOT mix.” And those are wise words that we can all agree on.

You must be logged in to leave a reply.